“Most of the pellet plants are small with an average annual capacity of around 9 000 tonnes. After pellet shortage problems in 2013 when only around 29 000 tonnes was produced, the sector has shown exponential growth reaching 88 000 tonnes in 2016 and is projected to reach at least 290 000 tonnes by 2021″

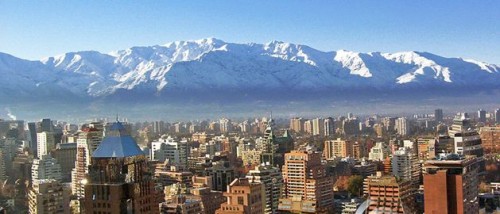

Chile obtains 23 percent of its primary energy from biomass. This includes firewood, a fuel widely used in domestic heating but also linked to local air pollution. In recent years, new technologies and cleaner and more efficient biomass fuels, such as pellets, are making headway at a good pace. Dr Laura Azocar, a researcher at the University of La Frontera, offers insight on the context and current state of markets and technologies related to pellet production in Chile.

ACCORDING TO DR AZOCAR, the use of firewood as a primary energy source is a particular feature of Chile. This is related to Chilean traditions and culture, in addition to the abundance of forest biomass, the high cost of fossil fuels, and cold and rainy winters in the central-southern zone.

A forest country

To contextualize this statement, it should be mentioned that Chile currently has 17.5 million hectares (ha) of forest: 82 percent natural forest, 17 percent plantations (mainly pines and eucalyptus) and 1 percent mixed production.

This has meant that despite the rapid growth experienced by the country, with a current per capita income of US$21 000 per annum and life expectancy of 80 years, it remains an underdeveloped in terms of home heating systems.

In fact, of the total energy consumed for heating, 81 percent comes from firewood, which means that around 1.7 million households in Chile currently use this fuel, reaching a total annual consumption of over 11.7 million m³ of wood.

More efficient alternatives

The high consumption of firewood is also linked to air pollution in Chile. 56 percent of the population, that is, close to 10 million people are exposed to annual concentrations of 20 mg per m³ of particulate material (PM) less than 2.5 pm (PM2.5).

Roughly half of this PM2.5 is attributed to the combustion of firewood/This is due to a number of factors such as poorly dried wood, low stove efficiency and poor insulation of homes. In addition, although the combustion of firewood is assumed as carbon dioxide (C02) neutral, the low efficiency of the stoves has implied C02 emissions equivalent to that emitted by kerosene and liquefied gas stoves.

In recent years, the increase in levels of education in Chile has resulted in a more empowered society that has begun to manifest demands related to the preservation of natural heritage and care for the environment.

Together with the above, an exponential development of research and the generation of advanced human capital has enabled the country to face these challenges through the search of new technologies and new fuels that address the existing need for home heating. One of these alternatives has been the production of pellets.

Stove switch out

The interest in the use of pellets in Chile was initiated around 2009 during which time the import of pellet stoves and boilers from Europe began. However, the high cost of importation proved a challenge and uptake was slow.

To popularise its use, the Ministry of Environment launched a stove and boiler replacement programme in 2012 for the residential and industrial sectors,Thanks to this switch- out programme, over 4 000 units were installed in 2012, a number that has since tripled with the incorporation of some local appliance manufacturers.

Half of these stoves and boilers are found in the residential sector, 28 percent in public institutions and around 22 percent in the industrial sector.

Not only wood pellets

Pellets in Chile are produced mainly from radiata pine (Pinus radiata), a common plantation species. In 2017, there were 32 pellet plants of varying sizes distributed in the Central and Southern areas of the country.

- Most of the pellet plants are small with an average annual capacity of around 9 000 tonnes. After pellet shortage problems in 2013 when only around 29 000 tonnes was produced, the sector has shown exponential growth reaching 88 000 tonnes in 2016 and is projected to reach at least 190 000 tonnes by 2020, said Dr Azocar.

Despite the abundance of forest biomass, this new “sustainable” Chilean society has generated interest on the part of entrepreneurs and researchers in searching for alternative raw materials for the production of densified biomass fuels. There are numerous National Research Centers and Universities that have developed research in this area.

At the University of La Frontera, the Waste and Bioenergy Management Center, which belongs to the BIOREN Scientific Nucleus and is associated with the Chemical Engineering Department, has developed a screening method for the identification of local biomass sources with energy potential.

Hazelnut husk and wheat straw

The study has identified hazelnut husk as the biomass with the best characteristics to be combusted. In addition, wheat straw has stood out for its high availability and the environmental impact generated by the usual practice of straw and stubble burning. Wheat is a major crop in Chile, grown on some 286 000 ha and generating about 1.8 million tonnes of straw annually.

In the case of hazelnut husks, although this biomass could be directly combusted, research has focused on its use for pellet production. The reason lies in facing the challenge of generating solid biomass fuels that adapt to the local reality, where public policies have led to the replacement of wood stoves with pellet stoves, to deal with the problems of local air pollution.

The results have been encouraging, preliminary findings suggest that these pellets would comply with the parameters established for pellets of woody origin according to ISO 17225-1 (2014).

In the case of wheat straw, torrefaction tests have been carried out in order to improve some characteristics of this biomass such as irregular size, low bulk density and low calorific value, amongst others.

Torrefaction, a thermal process carried out at moderate temperatures under an inert environment, was optimized specifically for this agricultural residue. Initial results suggest a significant increase of the retained energy and the calorific value at moderate operating conditions below 150℃.

The so-called black pellet produced on a pilot scale with this torrefied biomass was characterized according to the European standard ISO 17225-1 (2014). The results were auspicious, reaching an increase in apparent density from 469 kg per m³ to 568 kg per m³ thanks to the torrefaction pre-treatment process.

The pending challenges are aimed at finding technologies to reduce the content of microelements in torrefied wheat straw pellets in order to achieve a product that can enter the national market, helping to combat the environmental problems that affect the country.

Post time: Aug-10-2020