The correct installation and precise adjustment of the wood pellet mill press rollers are necessary for the pellet mill equipment to achieve greater capacity and prolong the life of the ring die and press rollers.

Loose roll adjustment reduces throughput and is prone to jams. Tight roll adjustment can result in die calendering and excessive roll wear.

Many customers will inquire about how to adjust the press roller of the pellet mill to make the machine in the best condition. The following is the installation and debugging method of the pressure roller

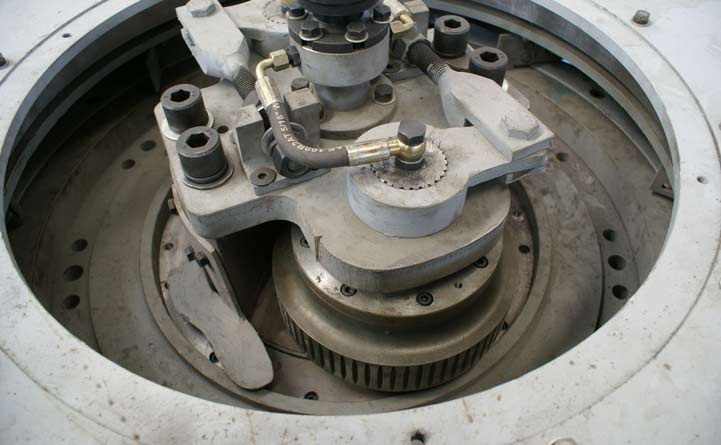

Wood pellet machine press roller installation:

1. First cut off the power and remove the dial;

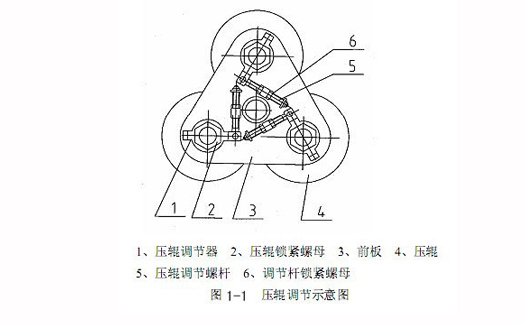

2. Then loosen the lock nut ② at the end of the three pressure roller support shafts;

3. Adjust the pressing roller to the position as far away from the ring die as possible;

4. Remove the adjusting screw ⑤ of each pressing roller;

5. Remove the front plate assembly of the pressing roller;

6. Remove the sealing cover on the pressing roller assembly, pay attention to the disassembly of the ferrule, and do not damage it. Remove the sealing ring, remove the pressure roller, pay attention to replace the lubricating oil on the roller bearing before replacing the pressure roller.

Debugging of pressure rollers of wood pellet machine:

1. Loosen the pressure roller locking nuts ② of the three pressure roller front plate assemblies;

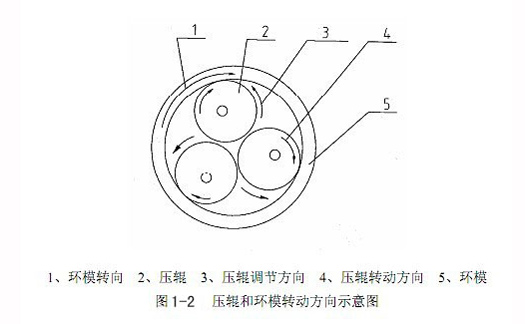

2. Adjust the lock nut ⑥ on the pressure roller adjusting screw ⑤ on the front plate, so that the pressure roller is counterclockwise against the ring die, and simultaneously rotate the ring die and the pressure roller for one week, and make the highest point of the inner surface of the ring die and the pressure roller. It is advisable to touch the highest point of the outer surface of the roller slightly, and then lock the lock nut on the adjusting screw;

3. During the adjustment process, if the adjustment screw has reached the limit position, and the gap between the pressure roller and the skew die has not been adjusted, remove the pressure roller adjuster ①, turn it to a position, re-install it, and then continue to adjust;

4. Adjust the other two rollers in the same way;

5. Lock the three pressure rollers and lock the nuts.

Note: During commissioning, the surface of the ring die and pressure roller should be thoroughly cleaned. Be sure to make the pressure roller close to the ring die counterclockwise, otherwise the ring die and the pressure roller may get stuck during operation, resulting in heavy losses. If it is found that the pressure roller is adjusted too tightly or too loosely after starting the machine, it should be re-adjusted according to the above steps. When debugging the pressure roller for the first time, the gap between the pressure roller and the ring die should be slightly larger. Production, check at any time after each shutdown, and adjust the gap between the rollers. If a ring die is used for a long time and is not replaced, the roller lock nut should be checked regularly to prevent loosening.

More technical questions about wood pellet machine are welcome to inquire!

Post time: Sep-19-2022