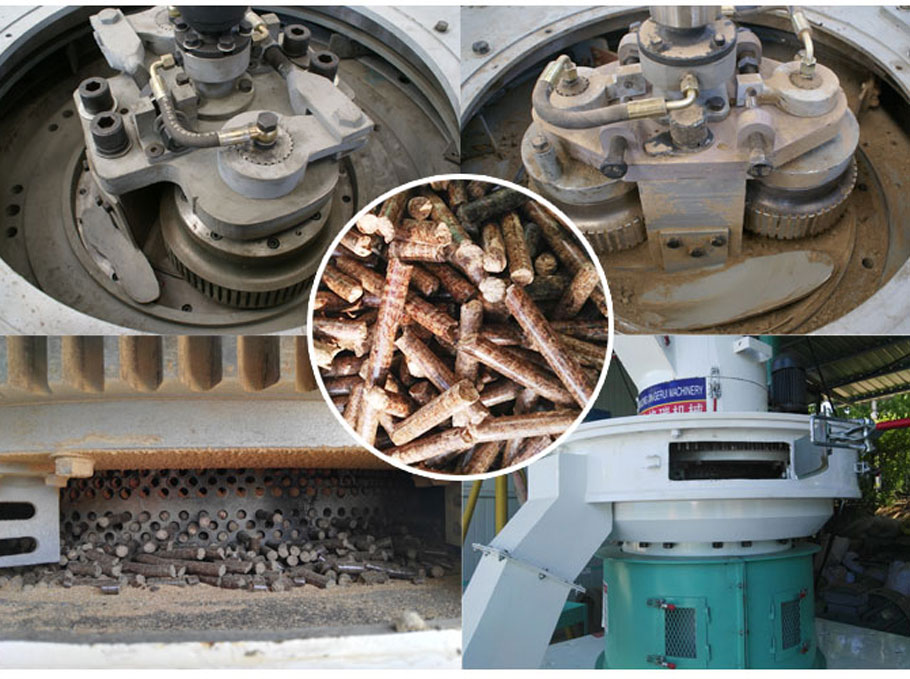

During the long-term use of the biomass pellet machine, the output will gradually decrease, and the production requirements will not be met.

There are many reasons for the decline in the output of the pellet machine. It may be that the user’s improper use of the pellet machine caused damage to a part of the pellet machine, or it was not installed correctly during installation, and it did not meet the standard requirements. , In short, the decline in output is a headache that affects the development of enterprises.

Today, the editor of Kingoro will focus on explaining to you how important the impact of the screen is on the output of the biomass pellet machine.

1. The length of the screen determines the screening efficiency, and the width of the screen determines the output of the biomass pellet machine. In order to increase the output, we can adjust the feeding method, so that the material must be fed along the full screen width, so that not only The output is increased, and the screen is fully utilized, avoiding the phenomenon of idle resources;

2. Improve the opening rate of the pellet machine screen: the larger the opening rate, the more materials will pass through the screen per hour, which is also very beneficial for improving the screening effect and increasing the output of biomass pellet machine equipment. method;

3. The use of wet screening can not only increase the output, but also reduce the dust emission generated during the screening process and pollute the atmosphere, which is also very beneficial to environmental protection. To reduce the batter porosity of the screen, consider adding more bouncing balls to clean the screen and use an ultrasonic device. If the mesh of the screen is blocked, the amount of material passing through the screen will be reduced, which will reduce the output and maintain the screen. Unobstructed holes are also one of the great ways to increase yields.

4. Increase the power of the motor: the power of the motor is the main power source for the screening work and the main force for completing the screening work. Properly increasing the power of the motor can increase the output of the pellet machine equipment;

5. The inclination angle of the pellet mill can be adjusted. Appropriate inclination angle is beneficial to reduce the thickness of the material and realize the screening of thin material layers. We all know that if the feeding amount is too large, the material will accumulate seriously, which will not only lead to the efficiency of screening It is very unfavorable if it is lowered, and it may damage the screen;

6. To reduce the batter porosity of the screen, consider adding more bouncing balls to clean the screen and use an ultrasonic device. If the mesh of the screen is blocked, the amount of material passing through the screen will be reduced, which will reduce the output. Keeping the screen openings unobstructed is also one of the best ways to increase production.

Post time: May-19-2022