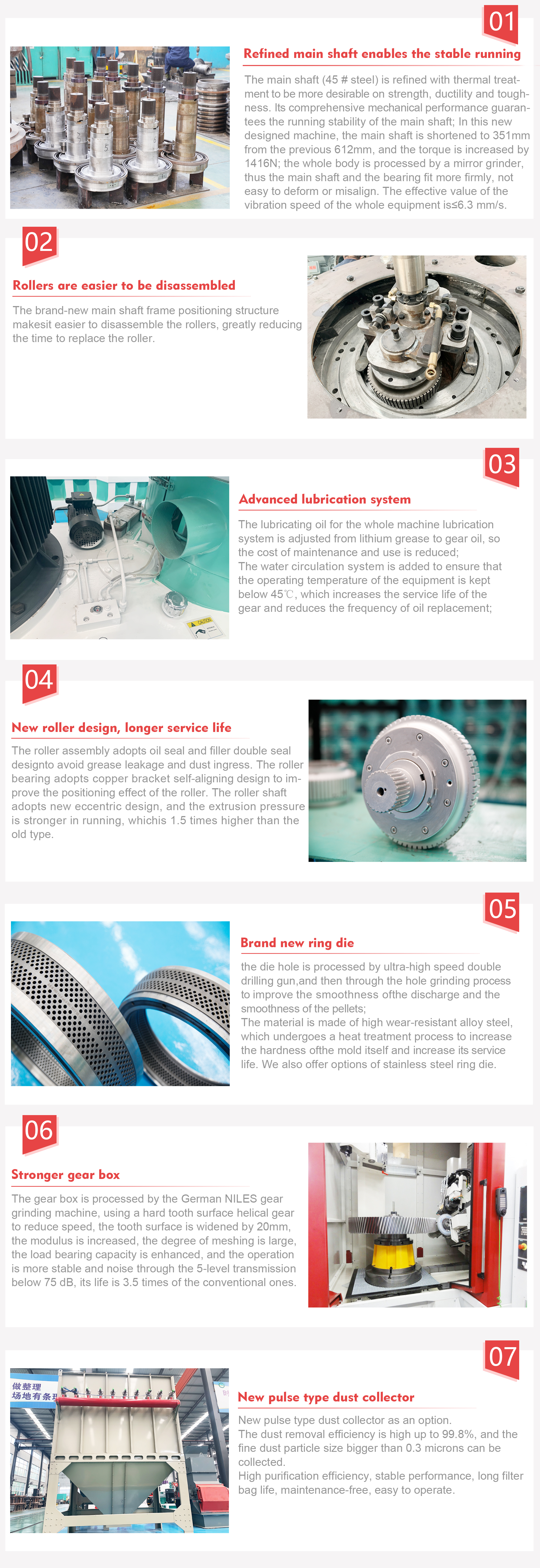

Biomass Pellet Machine

Biomass pellet machine can use agricultural and forestry waste such as wood chips, straw, rice husks, bark and other biomass as raw materials, and solidify them into high-density pellet fuel through pretreatment and processing. It is a fuel to replace kerosene, which can save energy and reduce emissions, and has good economic and social benefits. It is an efficient and clean renewable energy.

Specification

|

Model |

Power(kw) |

Capacity(t/h) |

Weight(t) |

|

SZLH470 |

55 |

0.7-1.0 |

3.6 |

|

SZLH560 |

90 |

1.2-1.5 |

5.6 |

|

SZLH580 |

90 |

1.0-1.5 |

5.5 |

|

SZLH600 |

110 |

1.3-1.8 |

5.6 |

|

SZLH660 |

132 |

1.5-2.0 |

5.9 |

|

SZLH760 |

160 |

1.5-2.5 |

9.6 |

|

SZLH850 |

220 |

3.0-4.0 |

13 |

|

SZLH860 |

220 |

3.0-3.5 |

10 |

Raw Material

Rice husk,straw,sunflower seed shell,peanut shell and other melon shell; Branches,trunks,bark,bamboo,and other wood scrap;All kinds of crop straw,rubber,cement,gray Slag and other chemical raw materials,etc.

Finished Pellet

Application

Delivery

Customer case

Our Service

24 Hours Online Service.

All-the-way tracking service offered from placing order to delivery.

Free training for operation, debugging and daily maintenance.

We can provide professional guide installation.

One year warranty and all-round after-sales service.

Customized design and flow chart are available for our clients.

Independent R&D team and strict & scientific management system.

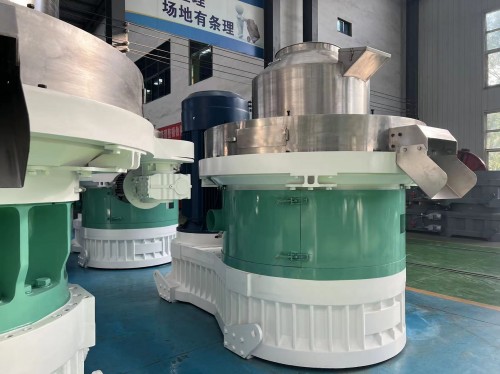

Our company

Shandong Kingoro Machinery was established in 1995 and has 29 years of manufacturing experience. Our company is located in beautiful Jinan, Shandong, China.

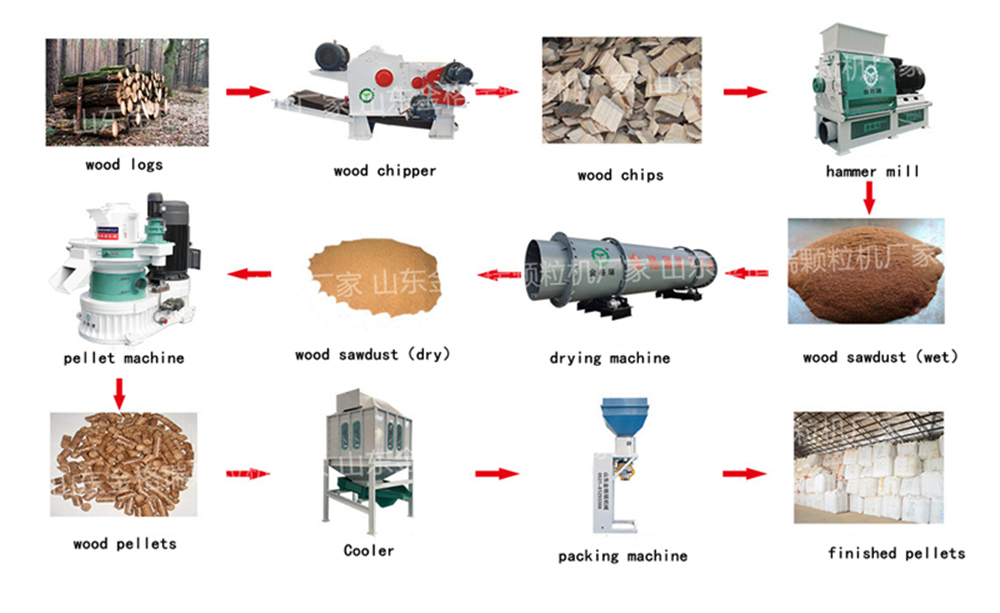

We can supply complete pellet machine production line for biomass material, include chipping, milling, drying, pelletizing, cooling and packing, according to different requirements of our customers. We also offer industry risk evaluation and supply suitable solution according to different workshop.