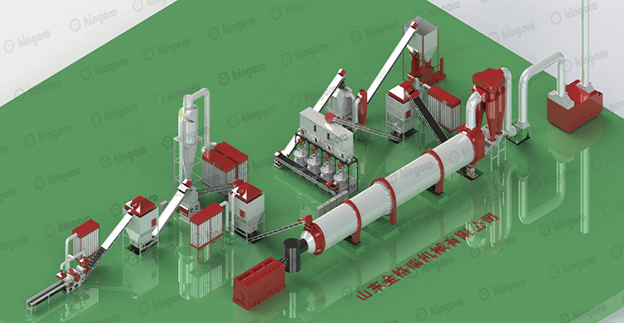

Pellet Production Line

Introduction of wood pellet production line

We can supply complete wood pellet machine production line for biomass material, include chipping, grinding, drying, pelletizing, cooling and packing, according to different requirements of our customers. We also offer industry risk evaluation and supply suitable solution according to different workshop.

The main equipment in the wood pellet production line is wood chipper--hammer mill--rotary dryer--wood pellet machine--pellet cooler--wood pellet bagging machine.

Wood Chipping Section (wood chipper machine):

Make the wood log/wood branches/wood blocks/bamboo... into smaller chips.

Finished products: 2-5cm

Grinding section (hammer mill):

Crush the wood chips/wood shaving/small blocks/grass/stalk...to sawdust/powder.

Finished products: 1-5 mm

Drying section (rotary dryer):

Dry raw material into suitable moisture to produce high-level pellets.

Finished moisture: 10-15%

Pelletizing section (wood pellet machine):

Press crushed and dry sawdust/rice husk/straw/grass... into pellets.

Finished pellets: 6/8/10mm.(Asian Market standard: 8mm; European Market standard: 6mm)

Cooling section (pellet cooler):

Cool high-temperature pellets before packing. The finished pellets are very hot(60-80℃) and realease moisture as they leave the pellet machine.

Packing section (wood pellet bagging machine):

Pack pellets into 20-50kg/bag or 1 ton bag. Easily to be transported to final users' site.

Factory photos